Cheese, a beloved food enjoyed by many worldwide, has a rich history spanning centuries. Cheese has evolved into a diverse and delectable culinary delight since its humble beginnings as a method to preserve milk. You can buy high-quality used cheese machines to help produce cheese for your needs. Have you ever wondered how this mouthwatering dairy product is made? Join us as we explore the fascinating process behind cheese production.

Milk Collection and Treatment

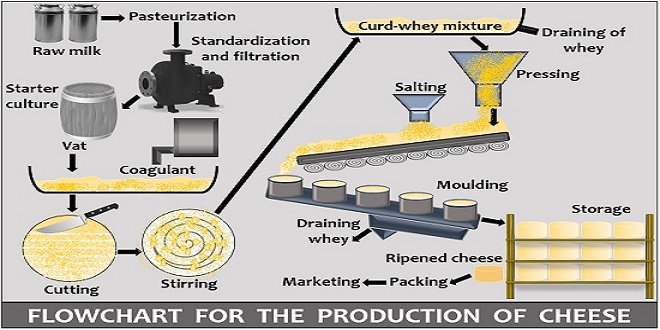

The first step in manufacturing cheese is collecting milk. Farmers carefully milk the animals, ensuring hygiene and quality standards. The milk is then transported to a dairy processing facility. Upon delivery, it undergoes a series of tests to ascertain its quality, freshness, and purity. Any impurities are promptly removed through filtration.

To initiate the cheesemaking process, the milk is pasteurized by heating it to a specific temperature for a designated period. Pasteurization eliminates harmful bacteria while retaining the milk’s nutritional properties. In some cases, raw milk is used, which skips the pasteurization step and is carefully monitored for safety throughout production.

Coagulation and Curdling

Once the milk is appropriately treated, it is time to transform it into curds and whey. This is achieved through coagulation, a process that involves the addition of a starter culture or microbial rennet to the milk. The starter culture consists of beneficial bacteria or fungi that convert lactose (milk sugar) into lactic acid, while rennet helps coagulate the milk proteins.

As the milk acidifies and the proteins coagulate, a gel-like substance called curd forms. The curds are then cut into small pieces, allowing the whey, a liquid byproduct, to separate. The size of the curds influences the final texture of the cheese. Larger curds produce softer cheese, while smaller curds produce a firmer texture.

Whey Draining and Curd Treatment

After the curds and whey have separated, the whey is drained, and the curds are collected. The curds are often stirred gently, promoting further whey expulsion and ensuring even moisture distribution. The degree of whey removal determines the cheese’s moisture content and texture.

The curds may undergo additional treatment to enhance their flavor and texture at this stage. Various techniques, such as heating, pressing, salting, or washing the curds with water or brine, can be used. This depends on the type of cheese being made. These techniques contribute to the development of distinct characteristics in different cheese varieties.

Aging and Ripening

Once the curds have been prepared, they are shaped into molds and left to age. The aging process allows the flavors and textures to develop further. Factors such as temperature, humidity, and time are crucial in the cheese’s maturation. While certain cheeses may mature quickly—in just a few weeks—others may take months or even years to develop the proper taste profiles.

The cheese undergoes biochemical changes during aging, including the breakdown of proteins and fats. This process leads to the development of unique flavors, aromas, and textures, making each cheese variety distinctive.

Conclusion

From the humble beginnings of milk collection to the intricate aging process, cheese production is a fascinating journey. The artistry and science behind this culinary tradition have given rise to countless flavors and textures that continue to delight cheese lovers worldwide. Therefore, the next time you enjoy a piece of cheese, stop to recognize the skill and love that went into its making.

Isaiminia World Breaking News & Top Stories

Isaiminia World Breaking News & Top Stories